Effects of different electrolytes on the structure and yield ofgraphene oxide produced via electrochemical exfoliation

Keywords:

Graphene, electrochemical exfoliation, electrolyte, quality, yield/production rate, graphiteAbstract

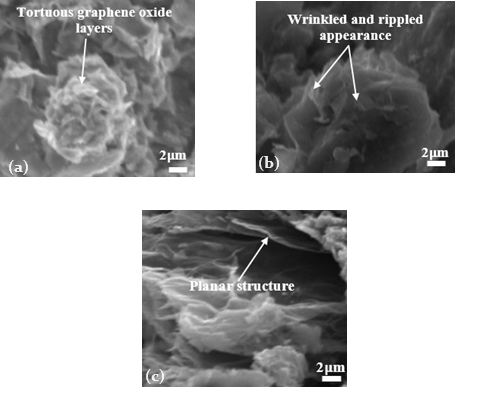

The most suitable electrolyte for graphene oxide synthesis, in terms of both production efficiency and quality, using the electrochemical exfoliation technique has been investigated and reported in this study. Simultaneous anodic and cathodic graphene oxide production using ten (10) different electrolytes, including acids (H2SO4, HCl, HNO3), bases (KOH, Ca(OH)2, Mg(OH)2, NaOH), and salts (NaCl, (NH4)2SO4, K2SO4), was studied under the same experimental conditions of bias voltage, graphite nature, exfoliation time, electrolyte molarity, and post-exfoliation treatments. Assessment of the graphene oxide structures and production rates was supported using Raman spectroscopy, high-resolution scanning electron microscopy (HRSEM), and EDS (energy dispersive x-ray spectroscopy), attached to the scanning electron microscope. Analysis of the results obtained reveals that H2SO4 showed the highest graphene oxide yield (86%) but with comparably low graphene oxide quality in terms of defect concentration, presence of oxygen functional group contamination, and crystallite properties. The aqueous NaCl, Ca(OH)2 and Mg(OH)2 electrolytes did not show any graphene oxide exfoliation effect. However, from the series of electrolytes examined, aqueous (NH4)2SO4 exhibited an excellent combination of efficient graphene oxide yield and high-quality characteristics due to its relatively high yield of 74% and superior quality of the produced graphene oxide with the comparatively lowest defect density, ?D, and highest C/O (carbon-to-oxygen) ratio. The tortuous, agglomerated, and planar layers of the distinct 2D graphene oxide sheets were also clearly revealed by the SEM images. In essence, the roles played by dissociated sulfate (SO42?), nitrate (NO32?), chlorides (Cl?), and hydroxides (OH?) ions in the series of complex electrochemical reactions toward the intercalation, exfoliation, yield, and properties of graphene oxide produced are discussed. From the series of electrolytes tested, aqueous (NH4)2SO4 emerged as the most relatively suitable electrolyte for the synthesis of graphene oxide because it combines both high yield and fine quality.

Published

How to Cite

Issue

Section

Copyright (c) 2023 Oluwole Adigun, Lasisi Egibunu Umoru, Temidayo Nancy Iwatan

This work is licensed under a Creative Commons Attribution 4.0 International License.