Theoretical Air Requirement and Combustion Flue Gases Analysis for Indigenous Biomass Combustion

Keywords:

Rice-husk, biomass combustion, theoretical combustion air, ultimate analysis, proximate analysisAbstract

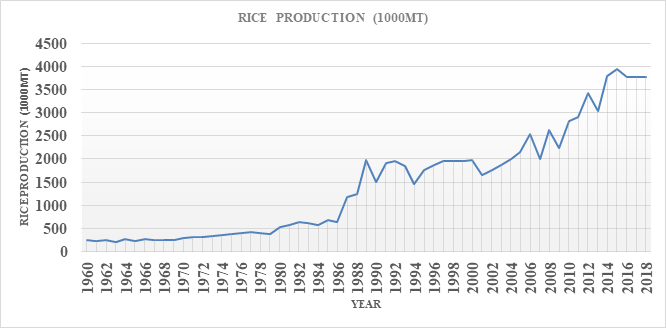

Rice-husk is one of the most abundant and commonly utilized biomass. It can be used directly to generate primary heating agent in combustion plants. However, emission characteristic of biomass usually vary depending on factors such as the variety of the parent plant, region of cultivation and climatic condition. Moreover, gases emission from biomass combustion could be detrimental to health; hence there is a need for information on the theoretical volume of air and flue gases required for optimal operation of combustion equipment. Thus, this work analyzed the theoretical combustion air requirement and the resulting flue gas volume of the abundant Nerica-rice-husk variety. Rice-husk samples were collected from southwestern part of Nigeria. The samples were characterised for their ultimate and proximate content. Afterward, the combustion analysis was carried out using the elemental composition obtained from the ultimate analysis to determine the theoretical combustion air requirement and the resulting flue gas volume. The proximate analysis result showed the moisture content level, fixed carbon content and ash content value of 10.93%,12.59% and 18.26% respectively for sample A and 9.80%, 20.76% and 14.81% for sample B. This reveals that Nerica-rice-husk is advisable for use as an alternative energy source in a combustion process. The calculated theoretical volume of air for sample A was 3.69596 (N m3/kg fuel), while 3.53947 (N m3/kg fuel) was obtained for sample B. This signifies a slight different between the combustion properties of rice-husk of same variety. It also showed that more quantity of theoretical air will be required to burn sample A compared to sample B, and that sample A will generate little more emissions compared to sample B. Hence, this study reveals the volume of air required for low emission combustion of Nerica-rice-husk in combustion plants.

Published

How to Cite

Issue

Section

Copyright (c) 2022 M. A. Lala, O. A. Adesina, O. J. Odejobi, J. A. Sonibare

This work is licensed under a Creative Commons Attribution 4.0 International License.