Heterogeneous Catalyzed Synthesis of Biodiesel from Crude Sunflower Oil

Keywords:

Crude sunflower oil, Calcium hydroxide, Transesterification, BiodieselAbstract

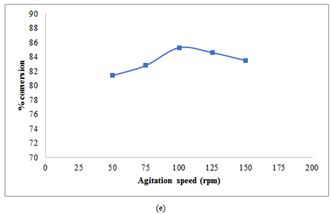

Biodiesel is the fatty acid alkyl esters that are used as the substitute for petro-diesel. The aim of the present work is to optimize biodiesel production from plant based non-edible crude oils with methanol using heterogeneous catalyst by transesterification for its commercialization. The factors affecting the biodiesel production from plant oils are volume of feedstock (oil), volume of alcohol (excess reactant), quantity of calcium hydroxide (catalyst), reaction time, temperature, and agitation speed. Transesterification is the reaction between acid and alcohol to produce ester in the presence of alkali catalyst. In this work, transesterification was carried out between crude sunflower oil and methanol in the presence of calcium hydroxide as catalyst. Finally, the maximum conversion of 85.6% was achieved at the optimum process parameters of 2 L of crude sunflower oil, 0.3 L methanol, 23 g of calcium hydroxide, reaction time of 24 h, temperature of 65 °C, and agitation speed of 100 rpm. The results showed that crude sunflower oil could serve as potential renewable substrate for biodiesel commercialization.Biodiesel is the fatty acid alkyl esters that are used as the substitute for petro-diesel. The aim of the present work is to optimize biodiesel production from plant based non-edible crude oils with methanol using heterogeneous catalyst by transesterification for its commercialization. The factors affecting the biodiesel production from plant oils are volume of feedstock (oil), volume of alcohol (excess reactant), quantity of calcium hydroxide (catalyst), reaction time, temperature, and agitation speed. Transesterification is the reaction between acid and alcohol to produce ester in the presence of alkali catalyst. In this work, transesterification was carried out between crude sunflower oil and methanol in the presence of calcium hydroxide as catalyst. Finally, the maximum conversion of 85.6% was achieved at the optimum process parameters of 2 L of crude sunflower oil, 0.3 L methanol, 23 g of calcium hydroxide, reaction time of 24 h, temperature of 65 ?C, and agitation speed of 100 rpm. The results showed that crude sunflower oil could serve as potential renewable substrate for biodiesel commercialization.

Published

How to Cite

Issue

Section

Copyright (c) 2022 Journal of the Nigerian Society of Physical Sciences

This work is licensed under a Creative Commons Attribution 4.0 International License.